Tuesday, April 30, 2013

Build Emergency Light Alarm

Warning! The circuit is connected to 220Vac mains, then some parts in the circuit board are subjected to lethal potential!. Avoid touching the circuit when plugged and enclose it in a plastic box.

Powered by two AA NI-CD batteries

Four switchable options

Circuit diagram

Parts:

R1 220K 1/4W Resistor

R2 470R 1/2W Resistor

R3 390R 1/4W Resistor

R4 1K5 1/4W Resistor

R5 1R 1/4W Resistor

R6 10K 1/4W Resistor

R7 330K 1/4W Resistor

R8 470R 1/4W Resistor

R9 100R 1/4W Resistor

C1 330nF 400V Polyester Capacitor

C2 10µF 63V Electrolytic Capacitor

C3 100nF 63V Polyester Capacitor

C4 10nF 63V Polyester Capacitor

D1-D5 1N4007 1000V 1A Diodes

D6 LED Green (any shape)

D7 1N4148 75V 150mA Diode

Q1,Q3,Q4 BC547 45V 100mA NPN Transistors

Q2,Q5 BC327 45V 800mA PNP Transistors

SW1,SW2 SPST Switches

SW3 SPDT Switch

LP1 2.2V or 2.5V 250-300mA Torch Lamp

SPKR 8 Ohm Loudspeaker

B1 2.5V Battery (two AA NI-CD rechargeable cells wired in series)

PL1 Male Mains plug

Device purpose:

This circuit is permanently plugged into a mains socket and NI-CD batteries are trickle-charged. When a power outage occurs, the lamp automatically illuminates. Instead of illuminating a lamp, an alarm sounder can be chosen. When power supply is restored, the lamp or the alarm is switched-off. A switch provides a "latch-up" function, in order to extend lamp or alarm operation even when power is restored.

Circuit operation:

Mains voltage is reduced to about 12V DC at C2s terminals, by means of the reactance of C1 and the diode bridge (D1-D4). Thus avoids the use of a mains transformer. Trickle-charging current for the battery B1 is provided by the series resistor R3, D5 and the green LED D6 that also monitors the presence of mains supply and correct battery charging. Q2 & Q3 form a self-latching pair that start operating when a power outage occurs. In this case, Q1 biasing becomes positive, so this transistor turns on the self latching pair. If SW3 is set as shown in the circuit diagram, the lamp illuminates via SW2, which is normally closed; if set the other way, a square wave audio frequency generator formed by Q4, Q5 and related components is activated, driving the loudspeaker. If SW1 is left open, when mains supply is restored the lamp or the alarm continue to operate. They can be disabled by opening the main on-off switch SW2. If SW1 is closed, restoration of the mains supply terminates lamp or alarm operation, by applying a positive bias to the Base of Q2.

Notes:

Close SW2 after the circuit is plugged.

This circuit was awarded with publication in ELECTRONICS WORLD "Circuit Ideas", September 2001 issue, page 708.

author: RED Free Circuit Designs

Friday, April 26, 2013

A Handy Pen Torch

This regulated dc provide is used to power two power white LEDs D4 and D6. Resistors R3 and R5 restricts the output present (and hence the light output) of IC1 and IC2 circuits respectively. Besides these parts, one purple colour LED (D2) is integrated in the primary circuit which works as a battery charging provide input indicator. Resistor R1 restricts the operating current of this LED.

Pen Torch Electronic Circuit Schematic

One very simple but dependable ac primarys powered battery charger circuit for the at hand pen torch can also be included here. Basically the pen torch circuit is a continuing current charger wired round Transistor T1 (BC636), energyed by using a 12v/350mA step down transformer and associated elementsD1, D2 and C1.

AC majors powered battery charger for the pen torch

Red LED (D3) provides a set voltage reference to the base of T1, with the assist of resistor R2. (During charging course of, Diode D1 in the primary circuit stop reverse current waft from the battery pack when charging input supply is absent.) After construction of the pen torch circuit, match the assembled unit inside of a small plastic enclosure for security and comfort.

Friday, April 12, 2013

Rear Fog Lamp For Vintage Cars

According to current legislation in many countries, vintage cars must also be fitted with a fog lamp at the rear. In modern cars, there is a bit of circuitry associated with the fog lamp switch to prevent the fog lamp from going on when the lights are switched on if the driver forgot to switch it off after the last patch of fog cleared up. The circuit described here extends that technology back in time. The circuit is built around a dual JK flip-flop (type 4027). T3 acts as an emitter follower, and it only supplies power to the circuit when the lights are switched on.

For safety reasons, the supply voltage is tapped off from the number plate lamp (L2), because it is on even if you accidentally drive with only the parking lights on. The wire that leads to the number plate lamp usually originates at the fuse box. As the states of the outputs of IC1a and IC1b are arbitrary when power is switched on, the reset inputs are briefly set high by the combination of C1, R1 and T1 when the lights are switched on (ignition switch on). That causes both Q outputs (pins 1 and 15) to go low. IC1a and IC1b are wired in toggle mode (J and K high).

The Set inputs are tied to ground (inactive). The driver uses pushbutton switch S1 to generate a clock pulse that causes the outputs of the flip-flops to toggle. The debouncing circuit formed by C2, R4 and T2 is essential for obtaining a clean clock pulse, and thus for reliable operation of the circuit. C1 and C2 should preferably be tantalum capacitors. The Q output of IC1b directly drives LED D1 (a low-current type, and yellow according to the regulations). The Q output of IC1a energises relay Re1 via T4 and thus applies power to the rear fog lamp L1.

Circuit diagram:

Rear Fog Lamp Circuit Diagram For Vintage Cars

Free-wheeling diode D2 protects T4 against inductive voltage spikes that occur when the relay is de-energised. In older-model cars, the charging voltage of the generator or alternator is governed by a mechanical voltage regulator. These regulators are less reliable than the electronic versions used in modern cars. For that reason, a Zener diode voltage-limiter circuit (D3 and R9) is included to keep the voltage at the emitter of T3 below 15 V and thus prevent the 4027 from being destroyed by an excessively high voltage.

The supply voltage for the circuit is tapped off from the fuse box. An accessory terminal is usually present there. Check to make sure it is fed from the ignition switch. The pushbutton switch must be a momentary-contact type (not a latching type). Ensure that the pushbutton and LED have a good ground connection. Fit the LED close to the button.

The following ‘Bosch codes’ are used in the schematic:

- 15 = +12 V from ignition switch

- 58K = number plate lamp

- 86 = relay coil power (+) IN

- 85 = relay coil power OUT

- 30 = relay contact (+) IN

- 87 = relay contact OUT

Author: Eric Vanderseypen - Copyright: Elektor Electronics Magazine

Wednesday, April 10, 2013

Sub Woofer and Controller Rise

all of sub woofers use a immense speaker driver in a immense box, with tuning vents & all the difficulties (& vagaries) that conventional operation entails. By conventional, I mean that the speaker & cabinet are operated as a resonant technique, using the Thistle-Small parameters to get a box which will (if everything works as it ought to) provide excellent performance.

The check methods I used are applicable to any combination, but in general I recommend either a single giant driver or a pair of (say) 300mm units. The next hurdle is the amplifier needed to drive the speaker. This is not trivial. If the selected driver has a sensitivity of 93dB / W @ one metre, then you can safely assume that the efficiency will be less than this below resonance, by a factor of possibly 6dB or more. In case you are used to driving a sub with 100W, this means that you have increased the power to 400W - although this is an over-simplification.

If they are to operate the sub from 60Hz (my aim from the outset), they will increase the power by 12dB for each octave, so if 20W is necessary at 60Hz, then at 30Hz this has increased to 320W, & at 15Hz, you will require over 5kW.

Fortunately, the reality is a tiny different, & 400W or so will be over sufficient for a powerful process, due chiefly to the fact that the energy content in the low bass region is not normally all that great. (Although some program material may have high energy content, in general this is not the case). The EAS process augments the existing process, which is allowed to roll off naturally - contrast this with the normal case, where a crossover is used to separate the low bass from the main process, so existing speaker capability is lost.

The controller is (actually very) simple, & the circuit is shown in Figure one. An input buffer ensures that the input impedance of the source does not affect the integrator performance, & allows summing of left & right channels without any crosstalk. The output provides a phase reversal switch, so that the sub can be properly phased to the remainder of the process. If the mid-bass disappears as you advance the level control, then the phase is wrong, so switch to the opposite position.

The integrators (U1B & U2A) include shelving resistors (R6 & R9), & the capacitor / resistor networks (C1-R4, C3-R7) be positive that signals below 20Hz are attenuated. In case you dont require to go that low, then the worth of the caps (or the resistors R4 & R7) can be reduced. I used four.7uF caps, & these are non-polarized electrolytic - a high value was needed to keep the impedance low to the integrators. I originally included the dual pot (VR1) to permit the upper frequency roll off to be set - however it does no such thing (as described above). The final output level is set with VR2, which may be left out if your power amp has a level control.

The unity gain range (using a 20k pot as shown) is from 53Hz to 159Hz. This ought to be sufficient for most systems, but if desired, the resistors (R5 & R8) can be increased in value to 22k, or you can select a bigger value pot. Using 22k resistors & the 20k pot will give a range from 36Hz to 72Hz.

The input must be a standard full range (or for a stampeded method, the whole low frequency signal). Do not use a crossover or other filter before the EAS controller. For final modification, and to integrate the method in to your listening room, I recommend the constant-Q equalizer. The final result using this is extraordinarily nice - I have flat in-room response to 20Hz!

The EAS method is surprisingly simple to set up with no instrumentation. Of coursework in case you have an SPL meter & oscillator you can also confirm the settings with measurements. Keep in mind that the room acoustics will play havoc with the results, so unless you require to drag the whole method outside, setting by ear might be the simplest. Even in case you did get it exactly right in an anechoic surroundings, this would alter one time it was in your listening room anyway.

It takes a small experimentation to get right, but is surprisingly simple to do. When properly set, a check track (or bass guitar) ought to be smooth from the highest bass note to the lowest, with no gross peaks or dips. Some are inevitable because of room resonances & the like, but you will discover a setting that sounds "right" with small difficulty.

I measured 80dB SPL at one meter in my workshop (sub-woofer perched on a chair in more or less the middle of the space) with at 25Hz & 70W. This improved dramatically when the unit was installed in the listening room, but as I said earlier, there is usually not a lot recorded below around 35Hz. The longest pipe on the organ is usually about 16Hz, but larger pipes still may be used. It was found necessary to cease group of diapasons (able to 8Hz) in the famous Sydney Town Hall organ because when they were used, the very low frequency caused building destroy.

Monday, April 8, 2013

Low Voltage Step Down Converter

The essential advantages are:

- small (but still manually solderable) SMD package;

- high operating frequency (750 kHz) => small external inductor;

- integrated power MOSFETs => high efficiency (up to 95 %);

- no external switching diode necessary.

You can thus use this device to build a very compact, highly efficient voltage converter. A sample layout generated by the author is available as a file on the Elektor website. The TSOP62000 provides an internal reference potential of 0.45 V, which can be used to set the output voltage in the range of 0.5 V to 5 V by means of resistors R2 and R3. The formula for this is: Vout = 0.45 V + (0.45 V) × (R2 / R3) For relatively low voltages, the value of inductor L1 should be 10 µH, but a value of 22 µH is better if the output voltage is 3.3 V or more. The input voltage can be anywhere in the range of 2 V to 5.5 V, and of course it has to be higher than the desired output voltage. The output voltage is 3.3 V with the indicated component values and an input voltage of 5 V. If you want to reduce the component count even further, you can use a member of the family with a fixed output voltage. The available voltages are 0.9, 1.0, 1.2, 1.5, 1.8, 1.9, 2.5, and 3.3 V. With this approach you can omit R2, R3 and C3, so the output can be connected directly to pin 5.

Saturday, April 6, 2013

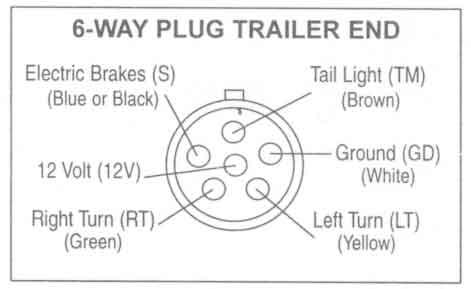

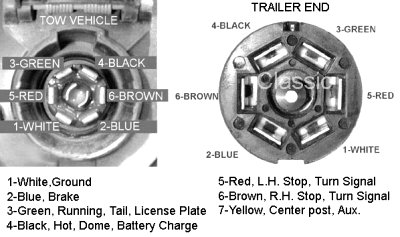

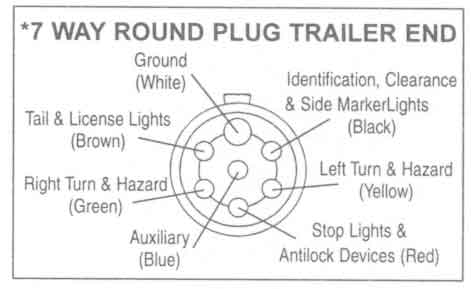

Trailer Wiring Diagram Connectors Pinoutcircuit Schematic

Trailer Light Wiring Typical Trailer Light Wiring Diagram.

Trailer Wiring Electrical Connections Are Used On Car Boat And.

Typical 7 Way Trailer Wiring Diagram Circuit Schematic.

Trailer Wiring Diagrams Johnson Trailer Sales Colfax Wisconsin.

Way Trailer Wiring Diagram And Connectors Pinout Circuit Schematic.

Post It But I Ll Try To Diagram It Here.

Pj Trailers Plug Diagram.

Troubleshooting Trailer Wiring.

Trailer Wiring Diagrams Johnson Trailer Sales Colfax Wisconsin.

This Allows You To Connect Up The Wiring To Tow A Caravan Or Trailer.

Thursday, April 4, 2013

A 12V Car Charger For ASUS Eee Notebook

- 2x 10k resistor (R1 & R4)

- 2x 22k resistor (R2 & R3)

- 1x 1.5k resistor (R5)

- 1x 120μF 25v electrolytic capacitor (C1)

- 1x 2200μF 16v electrolytic capacitor (C2)

- 1x 1N5822 Schottky diode (or equivalent)

- 1x 9.1v 0.5W Zener diode

- 1x BC337 NPN transistor

- 1x LM2576T-ADJ IC

- 1x 100uH, 3A inductor (e.g. Pulse PE92108KNL)

- 25°C/W or better minature heatsink (e.g. Thermalloy 6073)

- Cigarette lighter plug with 3A fuse and 2.1mm DC plug (e.g. DSE P1692)

- 2.1mm DC chassis mount socket

- 1.7mm x 4.75mm (ID x OD) DC plug and cable

- Small plastic enclosure

Tuesday, April 2, 2013

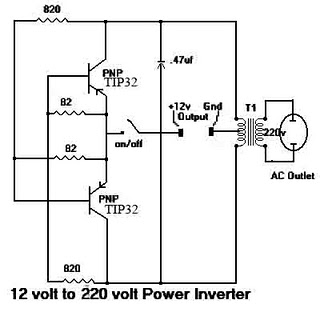

Simple Inverter with Two Transistors

Inverter circuit is very simple and easy to assemble and is perfect for just starting to learn to assemble electronic circuits, you can use the transformer 2A to produce about 20 watts output. Do not forget to install coolers in its transistors. good luck.